At Synergy Machine Support, we specialize in providing experienced maintenance personnel to the mining industry. Our experts focus on repairing and maintaining heavy mobile equipment, ensuring your operations continue without interruption. With a team of seasoned professionals, we handle critical equipment such as haul trucks, dozers, loaders, drills, and excavators, allowing us to quickly diagnose and resolve issues.

Revitalizing Mobile Equipment with Rebuilds In addition to our maintenance services, we breathe new life into heavy mobile equipment through comprehensive rebuilds, delivering end-to-end solutions that enhance both performance and longevity. Whether refurbishing your existing fleet or sourcing second-hand machinery for a complete overhaul, our workshop is fully equipped to meet the rigorous demands of the mining and industrial sectors.

Our Core Services

Synergy Machine Support offers a range of services to keep your equipment in top condition:

- Complete mobile equipment rebuilds with new running gear

- Sourcing and refurbishing second-hand machinery to like-new condition

- Engine, transmission, hydraulic system replacements, and upgrades

- NDT frame testing for structural integrity and safety assurance

- Custom rebuild solutions tailored to your operational needs

- Preventive maintenance and scheduled servicing of heavy equipment

- Emergency breakdown support and quick response solutions

- Comprehensive safety compliance in all maintenance activities

Specialists in Heavy Mobile Equipment Maintenance and Rebuilds

At Synergy Machine Support, we specialize in providing experienced maintenance personnel to the mining industry. Our experts focus on repairing and maintaining heavy mobile equipment, ensuring your operations continue without interruption. With a team of seasoned professionals, we handle critical equipment such as haul trucks, dozers, loaders, drills, and excavators, allowing us to quickly diagnose and resolve issues.

Revitalizing Mobile Equipment with Rebuilds In addition to our maintenance services, we breathe new life into heavy mobile equipment through comprehensive rebuilds, delivering end-to-end solutions that enhance both performance and longevity. Whether refurbishing your existing fleet or sourcing second-hand machinery for a complete overhaul, our workshop is fully equipped to meet the rigorous demands of the mining and industrial sectors.

Our Core Services

Synergy Machine Support offers a range of services to keep your equipment in top condition:

- Complete mobile equipment rebuilds with new running gear

- Sourcing and refurbishing second-hand machinery to like-new condition

- Engine, transmission, hydraulic system replacements, and upgrades

- NDT frame testing for structural integrity and safety assurance

- Custom rebuild solutions tailored to your operational needs

- Preventive maintenance and scheduled servicing of heavy equipment

- Emergency breakdown support and quick response solutions

- Comprehensive safety compliance in all maintenance activities

Our Expertise

SAP Maintenance Planning and Labor Supply for Underground Mining Equipment

Enhance your underground mining operations with our comprehensive SAP maintenance planning and labor supply solutions. Our services streamline the planning, scheduling, and execution of maintenance tasks for critical underground mining equipment. By utilizing SAP’s advanced maintenance management system, we provide real-time tracking of equipment performance, work orders, and labor availability, minimizing downtime and boosting operational efficiency.

Focusing on labor supply, our system ensures the timely allocation of skilled technicians and resources, reducing equipment failures and enhancing productivity. Whether managing preventive maintenance, repairs, or inspections, our SAP-driven solution enables seamless coordination, ensuring reliable uptime for your mining machinery.

Gain complete visibility into labor scheduling, track resource utilization, and ensure safety compliance, all while reducing costs and maximizing asset performance with our tailored SAP maintenance planning for underground mining equipment.

Ensuring Structural Integrity with NDT Frame Testing

The structural integrity of heavy equipment is crucial for safety and longevity. That’s why we incorporate Non-Destructive Testing (NDT) into our rebuild process. Our NDT frame testing service provides a thorough inspection of equipment frames and structures, ensuring your equipment is structurally sound and ready to withstand the toughest mining conditions.

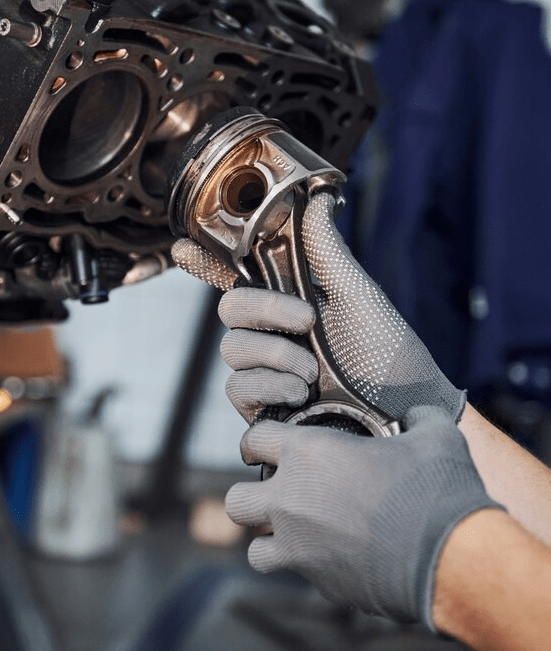

Mobile Equipment Rebuilds

Our skilled technicians specialize in full rebuilds of customer-owned equipment. From engines and transmissions to hydraulic systems, we replace essential components with new, high-quality running gear, ensuring that every part of your equipment is restored to peak operational performance. We use OEM parts or top-rated aftermarket alternatives to maximize reliability and minimize future maintenance needs.

Sourcing and Rebirth of Second-Hand Machinery

We also offer the option to source second-hand machinery and rebuild it to like-new condition. Using our extensive network, we identify equipment suitable for your needs, perform a full mechanical and structural overhaul, and deliver a cost-effective alternative to purchasing new machinery—without compromising reliability or performance.

Development of Maintenance Strategies for Underground Mining Equipment

Our comprehensive approach to maintenance strategy development for underground mining equipment is designed to optimize performance, increase efficiency, and minimize costly downtime. We specialize in creating customized maintenance plans that address the specific challenges of underground mining environments. Our services include predictive maintenance, condition monitoring, scheduled servicing, and risk-based inspections. By leveraging cutting-edge technology and industry best practices, we help you extend equipment lifespan, improve safety standards, and maintain uninterrupted productivity. Trust us to enhance the reliability and availability of your underground mining assets.

Underground Mining Equipment Maintenance Labour Supply

Our specialized maintenance labor supply service offers highly skilled and experienced technicians for the repair and upkeep of underground mining equipment. We provide customized solutions for mining operations of all sizes, ensuring your machinery operates at peak performance to maximize productivity and reduce downtime. Our team includes certified mechanics, electricians, and technical experts, experienced in servicing a wide range of underground mining equipment, including loaders, haulers, drills, and more.

Prioritizing safety, efficiency, and reliability, our labor supply services are available both on-demand and through long-term contracts, offering flexible staffing solutions tailored to the unique needs of your mining operation. Whether you require emergency repairs or scheduled maintenance, our team is equipped with the expertise and tools to ensure your equipment runs smoothly and meets industry standards.

Rely on us to maintain the core of your underground mining operations with a dedicated workforce committed to keeping your equipment in optimal condition.

Our Expertise

SAP Maintenance Planning and Labor Supply for Underground Mining Equipment

Enhance your underground mining operations with our comprehensive SAP maintenance planning and labor supply solutions. Our services streamline the planning, scheduling, and execution of maintenance tasks for critical underground mining equipment. By utilizing SAP’s advanced maintenance management system, we provide real-time tracking of equipment performance, work orders, and labor availability, minimizing downtime and boosting operational efficiency.

Focusing on labor supply, our system ensures the timely allocation of skilled technicians and resources, reducing equipment failures and enhancing productivity. Whether managing preventive maintenance, repairs, or inspections, our SAP-driven solution enables seamless coordination, ensuring reliable uptime for your mining machinery.

Gain complete visibility into labor scheduling, track resource utilization, and ensure safety compliance, all while reducing costs and maximizing asset performance with our tailored SAP maintenance planning for underground mining equipment.

Ensuring Structural Integrity with NDT Frame Testing

The structural integrity of heavy equipment is crucial for safety and longevity. That’s why we incorporate Non-Destructive Testing (NDT) into our rebuild process. Our NDT frame testing service provides a thorough inspection of equipment frames and structures, ensuring your equipment is structurally sound and ready to withstand the toughest mining conditions.

Mobile Equipment Rebuilds

Our skilled technicians specialize in full rebuilds of customer-owned equipment. From engines and transmissions to hydraulic systems, we replace essential components with new, high-quality running gear, ensuring that every part of your equipment is restored to peak operational performance. We use OEM parts or top-rated aftermarket alternatives to maximize reliability and minimize future maintenance needs.

Sourcing and Rebirth of Second-Hand Machinery

We also offer the option to source second-hand machinery and rebuild it to like-new condition. Using our extensive network, we identify equipment suitable for your needs, perform a full mechanical and structural overhaul, and deliver a cost-effective alternative to purchasing new machinery—without compromising reliability or performance.

Development of Maintenance Strategies for Underground Mining Equipment

Our comprehensive approach to maintenance strategy development for underground mining equipment is designed to optimize performance, increase efficiency, and minimize costly downtime. We specialize in creating customized maintenance plans that address the specific challenges of underground mining environments. Our services include predictive maintenance, condition monitoring, scheduled servicing, and risk-based inspections. By leveraging cutting-edge technology and industry best practices, we help you extend equipment lifespan, improve safety standards, and maintain uninterrupted productivity. Trust us to enhance the reliability and availability of your underground mining assets.

Underground Mining Equipment Maintenance Labour Supply

Our specialized maintenance labor supply service offers highly skilled and experienced technicians for the repair and upkeep of underground mining equipment. We provide customized solutions for mining operations of all sizes, ensuring your machinery operates at peak performance to maximize productivity and reduce downtime. Our team includes certified mechanics, electricians, and technical experts, experienced in servicing a wide range of underground mining equipment, including loaders, haulers, drills, and more.

Prioritizing safety, efficiency, and reliability, our labor supply services are available both on-demand and through long-term contracts, offering flexible staffing solutions tailored to the unique needs of your mining operation. Whether you require emergency repairs or scheduled maintenance, our team is equipped with the expertise and tools to ensure your equipment runs smoothly and meets industry standards.

Rely on us to maintain the core of your underground mining operations with a dedicated workforce committed to keeping your equipment in optimal condition.

Contact us today to learn more!

Contact us today to learn more!

Safety is Our Priority

In all our operations, we prioritize safety. Our team is fully trained in current safety protocols, certified for high-risk environments, and well-versed in hazard identification, use of personal protective equipment (PPE), and safe work practices. By partnering with Synergy Machine Support, you can be confident that both your equipment uptime and workplace safety are in expert hands.

By partnering with Synergy Machine Support, you can trust that our maintenance crews are not only focused on maximizing equipment uptime and performance, but also on creating a safer working environment.

Why Choose Us?

Whether you require short-term technical support or long term solutions Synergy Machine Support delivers the skilled manpower and safety-first approach needed to keep your operations running smoothly. We are committed to enhancing your productivity while safeguarding your people and assets.

Expertise and Experience

Our team consists of highly trained and experienced professionals who are experts in heavy equipment maintenance and operation. We ensure that every job is completed to the highest standard, on time, and within budget.

Customized Solutions

We understand that each client has unique needs. That’s why we offer tailored solutions to meet your specific requirements. Whether it’s a one-time repair or ongoing maintenance, we have you covered

Quality Assurance

We are committed to delivering exceptional quality in all our services. Our strict quality control measures ensure that every task is performed with precision and attention to detail.

Competitive Pricing

We offer competitive rates without compromising on quality. Our transparent pricing structure means no hidden fees, giving you peace of mind and value for your money.

Customer Satisfaction

Your satisfaction is our priority. We work closely with our clients to understand their needs and exceed their expectations. Our customer-centric approach has earned us a reputation for reliability and excellence.

Get in Touch

Ready to experience the best in heavy equipment maintenance and labor hire services?

Contact us today for a free consultation and quote. Our friendly team is here to assist you with all your needs.